Is your cabling a hot mess? Or maybe, your cabling is in better shape…as in, it’s barely passable?

Is your cabling creating unnecessary work for you and your team? We get it: managing your connections without DCIM is like Mario trying to fight Bowser without any power-ups. When you don’t have the tools you need, the deck is stacked against you.

Imagine, for a moment, knowing exactly what every device on your network is connected to – and what’s connected to that; imagine knowing that you know exactly which ports you have free. With DCIM, you can achieve this — and take back some control of your time, money, and network.

How?

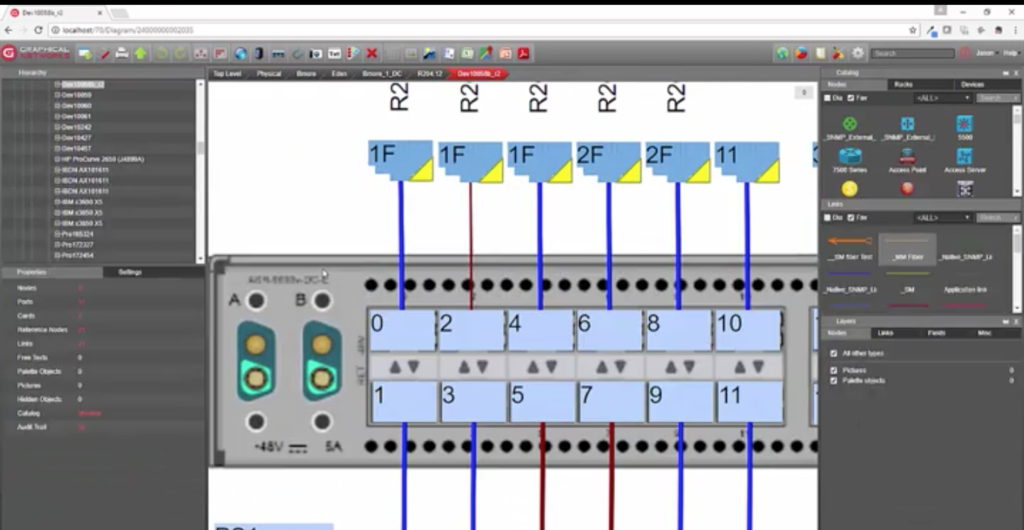

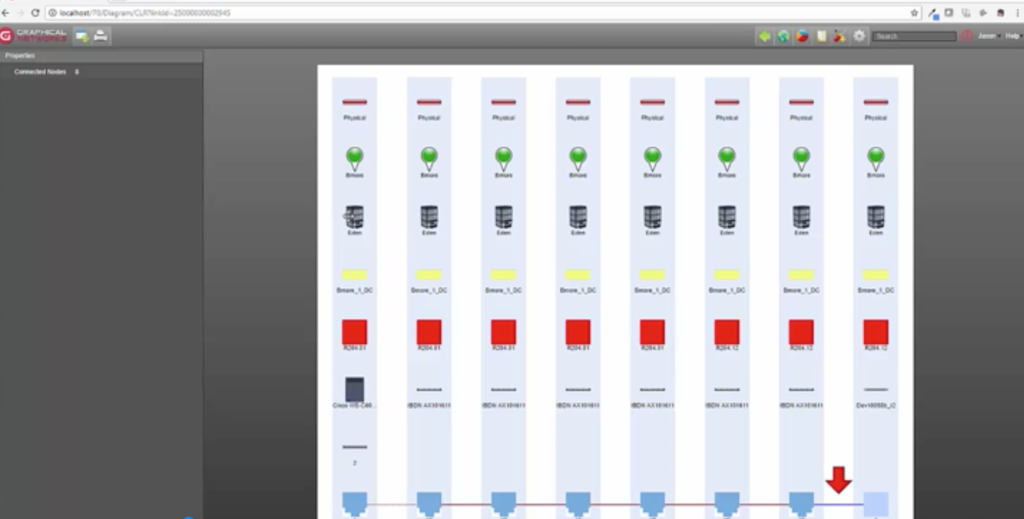

When you document your network with an IT visualization platform, you aren’t limited to just logical connections: you can document physical connections and see, in detail, what is connected to what. To do this, you access the circuit layout record (CLR) aka the physical path view.

The circuit layout record simplifies your work in the following three ways:

1. Troubleshooting

2. Planning

3. Decommissioning

Using our software netTerrain DCIM as an example, we’ll look at how the circuit layout record can save you some serious time and money (bear in mind that features and functions vary across different IT visualization platforms).

What the H*LL is a Circuit Layout Record?

So, maybe you’ve got a device which you need to investigate with your DCIM solution. In your initial view, you’ll see only what the device is immediately connected to. That doesn’t do you much good when you need to see what that device connects to and what is connected to that (and so on). Enter the circuit layout record to the rescue (with netTerrain, for example, you can generate one with the click of a button).

Once you’ve generated your circuit layout record, you get a full view of all of your connections; it drills down to the starting point of your device and what it connects to. So now, instead of being able to just view your device’s most immediate connection, you can view both end points and what is connected to those points.

Start Planning the Easy Way

Planning for new equipment installs without circuit layout records…it ain’t for the faint of heart.

How the heck can you accurately plan for new equipment installs when you don’t know what you have and what, or where, the connections are? To plan for the installation of new equipment, DCIM users have it easy: they can look at their connections up close to see what they have, and what they need, to save money and time.

So, how can you save money using circuit layout records for planning? Let’s say a manager from ‘Acme Enterprises’ is planning to connect a piece of equipment: she’ll need to figure out where the equipment is going to go and how it will connect. If she doesn’t know what she already has, or if the information she has isn’t accurate, she won’t know that she’s got 8 or 10 ports available for the new device. Not knowing that, she may end up purchasing equipment she doesn’t need.

What about saving time using circuit layout records? A manager at ‘Vandelay Industries’ thinks he has some ports available, so he sends someone out to the field to connect the equipment … then the phone rings. His person in the field informs him, “actually, I have zero ports available”. The field person then needs to spend time documenting: the end result is that two days or more are wasted.

Start Troubleshooting the Easy Way

Do you troubleshoot without circuit layout records? Someone needs to give you a ribbon, a pat on the back…and a day off.

When you’ve got a problem with a piece of equipment, and you need to know what it’s ultimately connected to in order to resolve the problem, how can you troubleshoot each end if you don’t know what these ends are? You can’t.

With DCIM, though, you can troubleshoot far faster and more effectively. If you’ve got a problem with a piece of equipment, you can just drill down to the device, generate the circuit layout record and actually view the full physical path.

For instance, when I’m troubleshooting, I can say “OK: let me look at the equipment involved in the path of this device.” Very quickly, I can see all the pieces in the puzzle. I can look at one end and go to that device or card, do some troubleshooting there and then view the other end of the device.

I save time by having access to key information. Information is power, or whatever the expression is: information gives you tools to go into the network and effectively troubleshoot.

Start Decommissioning the Easy Way

Decommissioning equipment without a circuit layout record to pull up: hey, want to go ahead and diffuse a bomb in the dark, while you’re at it? If you decommission a card, take out the connections, and think you’re done: you have a problem. You’re not done. You’ve only decommissioned one end.

What about those other connections? Some of those, of course, are cross-connections and don’t need to be decommissioned; some of them, however, do need to be removed (and you will want to note that the port is now free). If you leave ports that are no longer active, you’ll end up with inaccurate information (and that’s a pain in the a** when you’re troubleshooting and planning).

Start Managing the Easy Way

The English writer John Donne once famously said, “No man is an island” (although Simon and Garfunkel might disagree). The same goes for your devices: a device in your network isn’t an island unto itself and it doesn’t stand alone. If you need to fix or change it in anyway, it’s not just the device that changes: what you do to that device impacts your entire network. So, you really need to be able to view the ends of a device to fully understand how your network is impacted.

Bottomline? If you’ve been managing the network without DCIM (and circuit layout records), congratulations. That’s no easy feat.

If you’re starting to think there’s a better way, there is. The circuit layout record that comes with data center infrastructure management packs a lot of punch. With it, you can tackle downtime, save money and time, and maintain accurate information about the network (and give yourself a break).